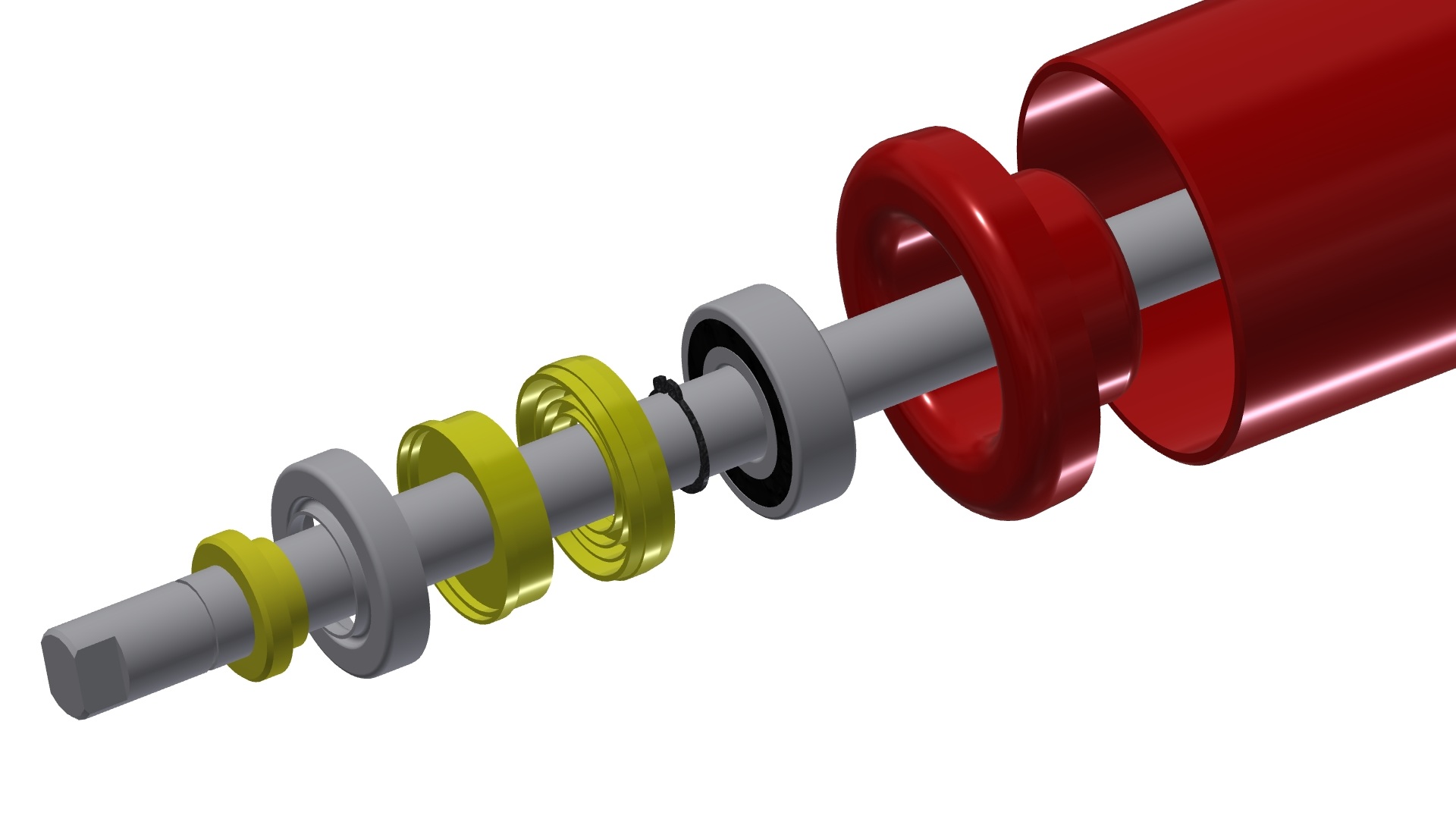

- The roller assembly consists of tube, end cups, shaft, ball bearings and labyrinth type seals.

- The end cups are manufactured on our premises made off deep drawn steel sheet, with a calibrated ball-bearing seat, so that they are concentric and correctly sized to suit the selected bearings.

- The shaft is made of cold drawn steel bars (tolerance h9).

- The ball-bearings are according to ABEC 1, chrome steel GCr15, C3 clearance, lithium greased, lubrication >30%...=40%

- The bearings are protected against dust and water penetration by highly sophisticated labyrinth seal system with an external zinc coated outer seal.

- Rollers standard finishing process: spray painting with two component epoxy or polyurethane coating and hot galvanizing.

- Rollers have very low starting and rolling resistance which allows low energy consumption.

- General fabrication tolerances for shafts : ±0.2 mm

- General fabrication tolerances for steel shell length : ±1.5 mm

- Max allowed movement of the shaft in roller with axial force 500N : 0.7mm

- Rollers have low Total Indicated Run Out (TIR) tolerance in order to reduce noise emissions.

Download our brochures from here: